Theory of Constraints

Theory of Constraints is a performance improvement technology that has been implemented in 1000’s of organizations world-wide since 1978.

TOC is characterized by “Focus and Leverage” — a combination that typically provides fast, direct and often massive performance improvements that consistently translate into bottom-line results.

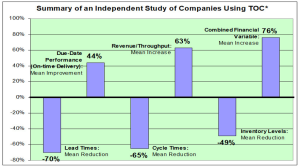

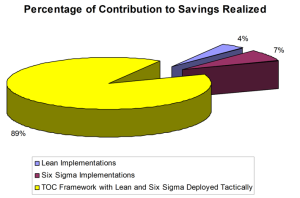

These 2 charts below taken from our “Introduction to TOC” workshop show exactly what we mean by “direct and often massive”… the Bar Chart is based on results from 400 published Case Studies. The Pie Chart is based on a 2-year, 23-Plant experiment.

The Bar Chart (from a book by Mabin & Balderstone) shows AVERAGE results.

What makes this so impressive is not just that the results are so big, so consistent, and counter-intuitive (inventory shrinking and lead times shrinking and on-time performance growing, while revenue grows 63%).

It’s that the 400 companies inevitably reflect a wide range of industries, business sizes, markets, in different economic cycles, with different levels of TOC expertise inside.

It’s rare that improvement technologies can be clearly compared. But a US Corporation with 23 Plants faced pressure from Managers in the different Plants to deploy Lean, or Six Sigma, or TOC.

The company decided to conduct an experiment and allow different Plants to implement the different technologies.

The results were stunning (to those who don’t understand TOC).

Over 2 years, just 7 of those 23 plants generated 89% of the results!

And … those were the plants that first deployed Theory of Constraints, then added Lean and/or Six Sigma afterwards.

Those plants out-performed the solo Lean and solo Six Sigma Plants by an order of magnitude.

That’s the power of Focus and Leverage.

TOC is applicable to any organization. However, Steve Jackson, the Principal of Jackson Constraints Group Inc is a specialist in applying TOC to small- to mid-size manufacturing organizations that fall into TOC’s “sweet spot.”

As illustrated in the charts, typical outcomes in these sweet-spot businesses that contribute to an order-of-magnitude increase in profitability include (And see the charts taken from some of our clients, below the Bullet Points, to support these claims inside our own practice):

- On-time delivery (make to order or ship from stock) increased to 98% and better.

- Lead times reduced 70% to 90%.

- WIP inventory reduced 50% to 90%.

- Finished Goods inventories — if applicable — reduced 25% to 75%.

- Operating expenses significantly reduced (scrap, overtime, expediting).

- A scheduling approach that means expediting chaos is significantly reduced.

- Production increased 20%, often 30%, occasionally 40% from essentially the same people and equipment.

- Sales & Marketing strategies and tactics to capitalize on the increased Productivity.

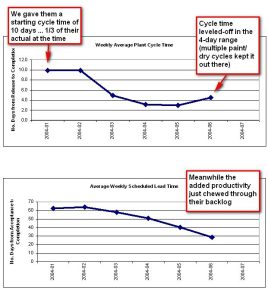

This client (below) had a 30-day internal cycle time. We helped them bring it down to 4 days with TOC. The increase in whole-plant Productivity enabled them to chew through their backlog at the same time. The increased shipments gave them a huge boost to their shipments and revenues over the period.

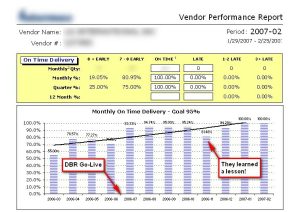

This is actually a report from a Customer of another client, reporting the on-time performance of our client.

You’ll see it was in the 70% to 80% range before we implemented TOC, and jumped to 90+ and ultimately 100% as soon as we implemented.

Just one time they fell back into old habits — and paid the price!

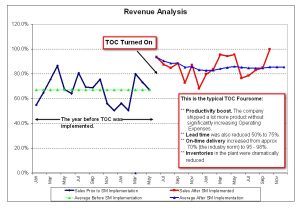

Another client … you can see the increase in Revenue that accompanies their TOC implementation and their increased whole-plant Productivity. At the same time they increased on-time performance and reduced lead times and WIP dramatically.

The implementation approach is characterized by gaining an extensive broad & deep buy-in to the TOC principles that provides a foundation for a customized detailed implementation plan created by the company’s resources with consulting & coaching assistance from Steve.

Realistically, JCG’s approach recognizes that resources in SMEs are frequently stretched to capacity (and beyond) even before the implementation project is added to the workload. So the implementation approach reflects a high degree of “done for you” and “done with you” as needed.

Theory of Constraints is also characterized by inclusivity; a TOC implementation can be even more effective when Lean and Six Sigma technologies are applied to take advantage of the TOC’s Focus & Leverage insights. And ERP software becomes far more valuable when it supports the TOC implementation.

Steve Jackson worked with TOC founder Eli Goldratt for 6 years commencing in 1988 then again, at Dr. Goldratt’s request, almost a decade later. He was one of the team who worked with Dr. Goldratt to develop, document, and teach the “TOC Thinking Processes;” and worked with Dr. Goldratt’s organization as TOC expanded from a Production solution to encompass Throughput Accounting, Distribution and Supply Chain Management, Critical Chain Project Management, Sales, Marketing, and “Strategy & Tactics” planning and deployment.

The typical Tactics that generate serious increases in profit include the following:

14 Tactics for Massive Profit Growth

1. Squeeze 20% – 40% more output from the same resources, and sell it at full price (or better). The only incremental cost is material costs — so the profit impact is large.

2. Reduce Operating Expenses by eliminating chaos from the plant. Typically reduce or eliminate expediting and overtime expenses.

3. Reduce Inventories by 25% to 50%. This frees-up cash to fund profitable growth; but it also supports performance improvement.

4. Use Throughput Accounting to understand the true impact of decisions on Net Profit. Conventional Cost Accounting does not tell you this! (Most Managers do not realize this.)

5. Use TOC 5 Focusing Steps and Throughput Accounting to identify process improvements that contradict conventional thinking but have a massive profit impact. Awareness of TOC & Throughput Accounting provides a game-changing Cause-Effect perspective.

6. Use Throughput Accounting to understand which products, Customers & Markets genuinely contribute the most towards Net Profit. This is usually stunning, and often a 180-degree change in perspective. It explains a lot!

7. Use Throughput Accounting to understand how you are using capacity to generate Profit. Often this illustrates that most capacity is being directed to low-profit business.

8. Use Throughput Accounting to create a pricing strategy that guarantees an excellent Return on Sales (ROS) in good times and in bad. Conventional pricing based on costs and margins limits profits and creates vulnerabilities.

9. Elevate the perceived value of your products by implementing best-in-class On-Time Delivery (service levels) and Lead Times. Our implementations use 99% on-time as the low-end; and Lead Times that are unmatched.

10. Elevate the perceived value of your Offerings, and price products higher than competitors while simultaneously increasing demand, using the “Mafia Offer” concept. Customers don’t care about your costs, but about the perceived value to them. It can be elevated!

11. Immunize the company from downturns with an aligned strategy, tactics, and Throughput Accounting. A counter-intuitive strategy positions you to be largely immune to market downturns in any sector.

12. Position the company to take business from any competitor, at any time, via a Decisive Competitive Edge (much more substantial than just a “Competitive Edge.”) When the market experiences a downturn, you simply take business from hapless competitors!

13. Position the company to manage aggressive sales growth with no deterioration in Lead Times or On-Time Delivery. This is non-trivial! Conventional methods and systems do not deliver this.

14. Convert the potential of Lean and Six Sigma technologies into faster, bigger Profit growth. Deploying Lean or Six Sigma in support of Constraints, 10 X’s the impact.

The beauty of the TOC methodology is that it always converts into increased profitability.

That’s the Goal — “To make more money, now and in the future.” It’s not just a hoped-for side effect!